Telephone:+86 13032112360

Mailboxsales@songjiangflex.com

Address:22F, Dinggu Business Center, Chengbei Road, Jiading District, Shanghai,China

In the domain of industrial upgrades, optimizing shower systems within factories is essential for boosting operational efficiency and ensuring safety. This analysis delves into the Wuhan Shenlong No.1 Factory’s shower system renovation project, highlighting the pivotal role played by bellows expansion joints in improving the system’s performance.

Bellows expansion joints are critical components in the renovation of factory shower systems. Their multifunctional nature addresses several key areas:

Temperature Variation Management: Factory shower systems often face significant temperature changes. Bellows expansion joints efficiently absorb thermal expansion and contraction, reducing stress on the pipeline network. This capability helps maintain the pipeline’s integrity, preventing damage from temperature-induced expansion.

Vibration and Shock Absorption: Industrial machinery operations generate considerable vibrations and shocks. Bellows expansion joints absorb these vibrations and impacts effectively, reducing their transmission to the shower system pipelines. This lowers noise levels and prevents potential damage from excessive vibration.

Compensating for Misalignments and Installation Errors: Installation of shower systems can lead to misalignments and errors. Bellows expansion joints, with their flexible design and movement accommodation, address these deviations. This ensures secure connections and optimal sealing performance within the pipeline system.

Extending Pipeline Lifespan: By alleviating stress and minimizing the impact of vibrations, bellows expansion joints help extend the lifespan of pipeline systems. This leads to reduced maintenance costs and enhances operational efficiency by minimizing downtime associated with repairs and replacements.

The Wuhan Shenlong No.1 Factory undertook a significant shower system upgrade to improve operational efficiency and ensure employee well-being. A crucial part of this project was the integration of bellows expansion joints within the shower system pipelines. These joints were strategically installed to manage temperature changes, absorb vibrations, and compensate for any installation errors or misalignments.

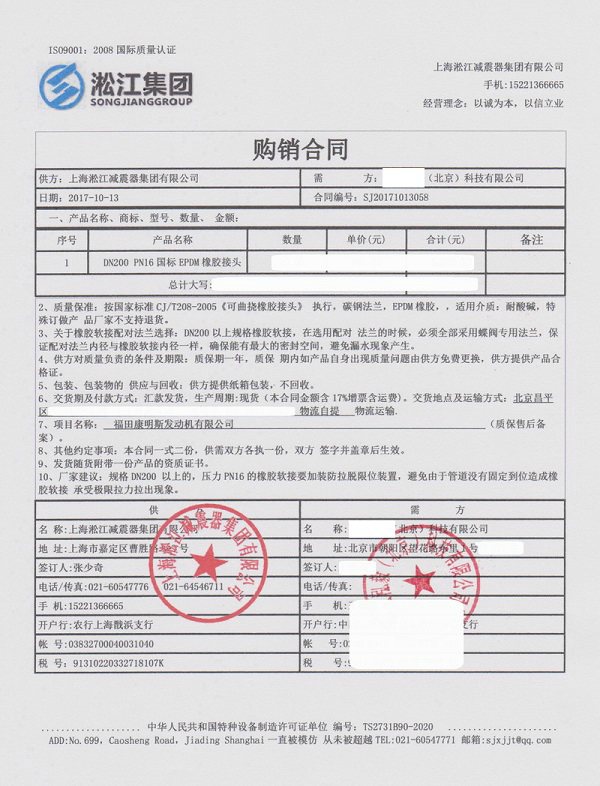

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

The successful renovation of the Wuhan Shenlong No.1 Factory’s shower system highlights the importance of incorporating bellows expansion joints in industrial infrastructure projects. By effectively managing temperature variations, dampening vibrations, and compensating for installation errors, these joints play a vital role in enhancing the functionality and longevity of factory shower systems. As industries focus on operational efficiency and workplace safety, the adoption of bellows expansion joints in shower system upgrades emerges as a highly recommended practice for achieving these goals.

Related Links:[EPDM] Rubber bellows expansion joints “desulfurization and denitration”

Service hotline

+86 13032112360