Telephone:+86 13032112360

Mailboxsales@songjiangflex.com

Address:22F, Dinggu Business Center, Chengbei Road, Jiading District, Shanghai,China

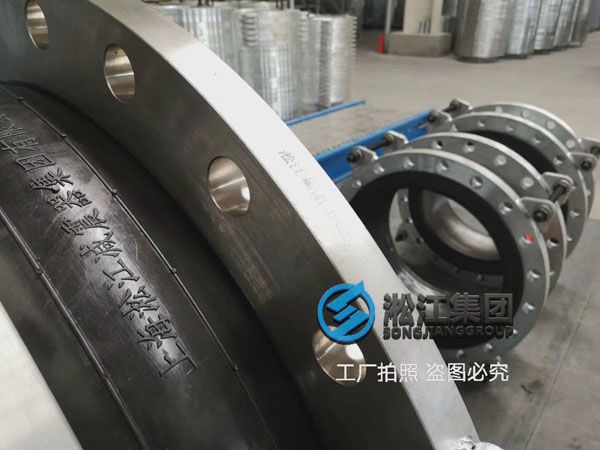

Installation site of blower axial expansion bellows in sewage plant

The official website of Shanghai Songjiang shock absorber Group Co., Ltd. introduces you: Spencer Power Mizer blower axial expansion bellows rubber sewage plant installation site, Songjiang Group provides high-quality axial expansion bellows rubber products for many sewage treatment plant blowers, with a 5-year warranty, durable, Help customers to save the cost of replacement and repairs.

[Spencer Power Mizer blower] Introduction:

Spencer Power Mizer blowers are multistage centrifugal units which handle air and other gases, working either as blowers or exhausters. They increase the pressure of the incoming air or gas by guiding it from one stage to the next through diffusers.

They are centrifugal because the flow through the blower is turned perpendicular to the axis of rotation.The blower casing has three main sections constructed of cast iron: inlet, return channels and discharge. The inlet and discharge are flanged and drilled to ANSI 125#/150# standards, which attached with ANSI flanged rubber bellows products.

External steel tie rods hold the return channels between the inlet and discharge sections. There are no external moving parts except the shaft that connects to the power source–typically an electric motor, but other drivers such as a steam turbine or internal combustion engine are available.

The internal rotor assembly consists of a steel shaft supporting cast aluminum alloy impellers with varying combinations of radial and backward curved blades. The impellers are individually dynamically balanced, then keyed to the shaft and the impeller/spacer stack is secured with a locknut. Finally, the complete rotor assembly is checked to be sure the total amplitude of vibration is no more than 0.23 in/sec at thebearing housing.

The rotor assembly is supported at both ends by antifriction bearings designed for an L-10 bearing life of 100,000 hours. Depending on intended blower use, either labyrinth seals or carbon ring seals are provided.

Related links: [SUS 304] Stainless steel flange drinking water grade Rubber bellows expansion joints

Service hotline

+86 13032112360