Telephone:+86 13032112360

Mailboxsales@songjiangflex.com

Address:22F, Dinggu Business Center, Chengbei Road, Jiading District, Shanghai,China

In recent years, the SAIC-GM-Wuling Liuzhou Factory has undergone significant upgrades as part of a broader effort to enhance its production capabilities. This state-of-the-art expansion includes the integration of advanced manufacturing technologies and optimized production lines, aimed at meeting the increasing demand for high-quality vehicles. A critical component of this modernization is the collaboration with Shanghai Songjiang Group, which has supplied essential bellows expansion to ensure the efficient and reliable operation of the factory’s upgraded systems.

SAIC-GM-Wuling Liuzhou Factory, a major player in the automotive industry, has a rich history of innovation and growth. The factory spans 89.2 million square meters and employs over 20,000 workers. It features modern production workshops focused on stamping, bodywork, painting, and final assembly. The factory’s annual production and sales figures are impressive, with a continuous upward trend in vehicle output.

To support such extensive operations, Shanghai Songjiang Group has provided their high-quality bellows expansion. These expansions play a vital role in maintaining the integrity of the factory’s complex piping systems. Designed to absorb vibrations and shocks generated by heavy machinery, Songjiang’s expansions help protect the infrastructure from potential damage, ensuring a smooth and uninterrupted flow of fluids and gases throughout the production process.

The flexibility of Songjiang’s bellows expansion is crucial in addressing thermal expansion and contraction within the factory’s piping network. This adaptability prevents pipe ruptures and leaks, thereby ensuring a safe and efficient working environment. Additionally, these expansions are instrumental in compensating for misalignments and offsets in the piping connections, which can occur due to the intricate layout of the manufacturing floor. This capability guarantees secure and leak-free connections between pipes and equipment, enhancing the overall stability of the factory’s operations.

Maintenance is another area where Songjiang’s bellows expansion offers significant advantages. Their design allows for quick and easy installation and replacement, minimizing downtime during repairs. This feature is essential for maintaining high productivity levels, as it ensures that necessary maintenance activities can be conducted swiftly and efficiently without causing prolonged disruptions to the production schedule.

Looking ahead, Shanghai Songjiang Group is committed to continuing its growth and innovation in the field of vibration absorption and expansion technology. With a strong focus on quality and customer satisfaction, Songjiang aims to expand its market presence and develop even more advanced solutions to meet the evolving needs of various industries. Their ongoing collaboration with leading manufacturers like SAIC-GM-Wuling highlights their expertise and dedication to supporting industrial advancements.

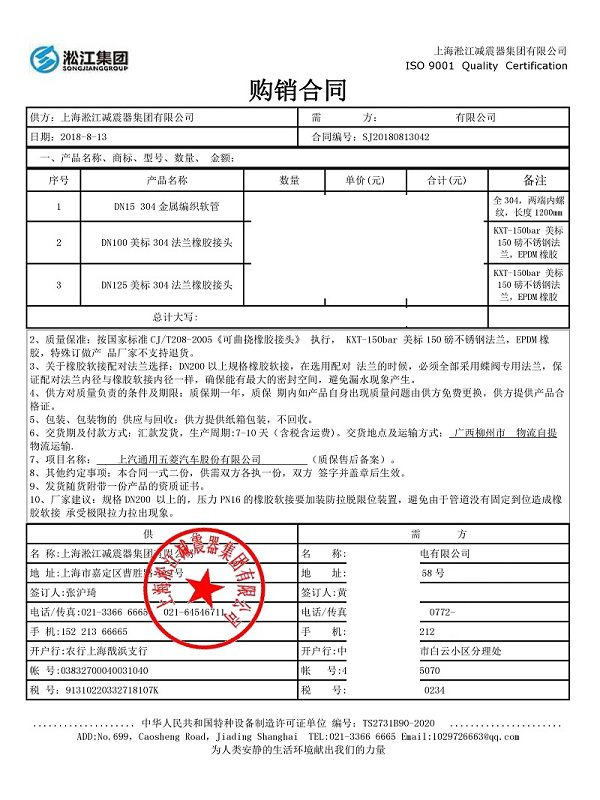

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, the integration of Songjiang bellows expansion at the SAIC-GM-Wuling Liuzhou Factory showcases the impact of strategic partnerships and advanced technology in driving efficiency and reliability in manufacturing. As Shanghai Songjiang Group continues to innovate and expand, their contributions will undoubtedly play a crucial role in shaping the future of industrial production.

Related links:[ANSI] Rubber bellows expansion joints “150bar”

Service hotline

+86 13032112360